[{

"name": "Newsletter Promo",

"id": "NewsletterPromo",

"class": "inlineCenter",

"insertPoint": "4",

"component": "15264767",

"requiredCountToDisplay": "0"

},{

"name": "Ad - Medium Rectangle CC01 - 300x250",

"id": "AdMediumRectangleCC01300x250",

"class": "inlineCenter",

"insertPoint": "8",

"component": "2963441",

"requiredCountToDisplay": "12"

},{

"name": "Ad - Medium Rectangle LC01 - 300x250",

"id": "AdMediumRectangleCC01300x250",

"class": "inlineCenter",

"insertPoint": "18",

"component": "2963441",

"requiredCountToDisplay": "22"

},{

"name": "Ad - Medium Rectangle LC09 - 300x250",

"id": "AdMediumRectangleLC09300x250",

"class": "inlineCenter",

"insertPoint": "28",

"component": "3252660",

"requiredCountToDisplay": "32"

}]

From the outside, Cal Poly looks the same as it ever was. Sure, there are spiffy new buildings and more students than ever crowding the walkways, but those same students are still sitting down at desks, being taught, and “learning by doing”—as they have since 1901.

Look a little closer, however, and you’ll see that students, and professors, are learning a little bit differently. Namely, the university—long a research backwater—has started to expand, and succeed, in its research efforts.

“Twenty years ago, research was a bad word around here,” said Dean Wendt, Poly’s interim Dean of Research. “We’ve been doing great things for students here for a long time, but if our faculty aren’t engaged out in the world, then that diminishes Poly’s reputation around the country.”

Seeking to shed that research-averse reputation, the university’s Academic Senate approved a resolution in 2011 officially adopting the “teacher-scholar model,” wherein teaching and scholarship are both emphasized as important, mutually reinforcing components.

That resolution was the latest, strongest step in a cultural shift toward expansion of research at Cal Poly that’s been advancing for more than 20 years. That shift has seen the annual total of external funding raised for research (a common benchmark metric for research prowess) rise from $8 million in the 1992-93 fiscal year to $26 million in fiscal year 2012-13.

In California, where the University of California cluster is regarded as a group of research schools and the California State University schools (including Cal Poly) are seen as teaching schools, Cal Poly is among the centers of education attempting to prove that research and teaching don’t have to be mutually exclusive.

“I think the supposed dichotomy between teaching and research is a bogus dichotomy,” Wendt said. “We recognize the pedagogical value of research now, and we also know that, for our faculty, their engagement within their discipline can improve their engagement in the classroom with students.”

A package deal

The shelves in Dr. Jay Singh’s office support the usual assortment of books and binders, but mostly there are bottles and cans. Hundreds and hundreds of bottles and cans.

Piled from floor to ceiling are aluminum and plastic, Coke and Pepsi, squat and elongated, flimsy and sturdy—Singh doesn’t discriminate. His desk contains the discards of his day’s packaging consumption: a Diet Coke can, an Arrowhead water bottle, and a large, metallic Lockheed Martin coffee mug.

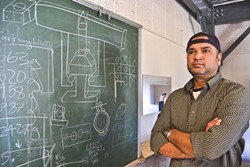

Singh is a professor of industrial technology at Cal Poly, and he also directs the school’s packaging program and lab. Though some might consider packaging dull or un-academic, Singh disagrees.

“Name a physical, retail product that you’ve bought recently,” Singh said. “I guarantee that item was packaged. Everything is packaged. Packaging just does its job so well that people often only think of the product.”

Singh seems at home in his packaging palace, casual in jeans and a backwards baseball cap, effortlessly describing his highly technical research with the Federal Aviation Administration.

Singh’s research with the FAA has three prongs: designing a new set of testing standards for safe air shipping, RFID (radio-frequency identification) hazard assessment on planes, and gauging the effectiveness of prototype lithium battery packaging, also on air shipments.

“Here at Poly and with our Packaging Dynamics Lab, we have the expertise to design and test packaging for anyone,” Singh said. “People don’t realize there is science, math, and art behind packaging—you can’t just throw things in a box and expect everything to be in one piece.”

For every “distribution packaging” class that Singh teaches, he has his students construct product-package systems for six wine bottles, which are then shipped from Paso Robles to Shanghai via DHL shipping. After testing in the lab, students release their creations into the world and hope the wine bottles emerge unscathed and display-ready. It’s kind of like an egg drop project, but with much loftier, transnational stakes.

“You’ve got temperature, humidity, shock, vibration, compression, pressure, and electro-static discharge,” Singh said, counting the potential damage factors on his fingers. “We design packages for the worst case scenario, and we’re trying to stay ahead of what’s to come.”

Outside of his work with the FAA, Singh’s lab has invented an award-winning fresh asparagus package now used 2.2 million times per year by Walmart, he has published more than 80 peer-reviewed journal articles, and he has also raised more than $3 million in competitive external grants and projects.

Ask Singh what he finds most rewarding, though, and he doesn’t hesitate for a second.

“There’s such a satisfaction in being an educator and getting to teach,” Singh said. “I’m excited coming to Poly every day at 7 a.m., and I feel like I’m getting paid to have fun.”

At the Packaging Dynamics Lab there are 20 to 30 students milling around the facility, and Singh answers their questions, offers input, and watches as they test out their packages.

Poly’s packaging program is currently ranked third in the country, and Singh said many students study here so they can “learn by doing” on elaborate, intimidating-sounding machines like the Lansmont Compression Tester, the LAB Transportation Simulator, and the TMI Edge Crush Tester.

“I don’t think our work in packaging is ever going to be done,” Singh said. “It’s an ever-evolving field that’s a $160 billion industry in the U.S. alone, and companies realize that university labs like ours are unbiased, and often better equipped.”

The crusade for clean plastic

Just a few buildings over, Dr. Keith Vorst, an associate professor of industrial technology, is conducting research on similar materials—namely, plastic—but for an entirely different purpose.

Vorst is a bundle of energy in his lab, eagerly pacing from one machine to the next and enthusiastically explaining the function of each piece of equipment, his fast-paced words often accompanied by evocative hand gestures.

“Basically, I care about what’s going from plastic into our food,” Vorst said, breathlessly. “We live, breathe, and eat plastic—it’s unavoidable.”

Vorst explained that his research—often done in collaboration with Dr. Wyatt Brown, a research scientist in the College of Agriculture—specifically focuses on the microbial safety and contamination levels of plastic packaging used to store common foods and beverages, such as heavy metals and low-molecular-weight compounds.

Vorst’s research, funded by both the U.S. government and private industry, has uncovered some disturbing results. Using high-tech testing methods to isolate potential contaminants (including sensor arrays, chromatography, spectroscopy, and inductively coupled plasma), Vorst has found significant levels of heavy metals and endocrine disruptors (chemicals that cause tumors, defects, and various health disorders) in widely used plastic packaging.

“People honestly believe that companies are testing their plastic, and it’s just not true,” Vorst said. “We’ve been taking this for granted for so long and people need to be aware of the truth. It’s scary stuff.”

Vorst said he advises everyone he meets to never heat up or freeze plastic containers, as both extreme temperatures can potentially cause increased leaching of contaminants into the food inside the container. If that temperature fluctuation occurs during the shipping process, however, Vorst said it’s out of the consumers’ hands.

Vorst pointed out that many smaller companies (and a few larger ones) do take steps to test and certify the safety of their plastic packaging, but many big companies are eager to pass the buck on testing to the U.S. government, which has been reluctant to enforce safe plastic standards thus far.

“It’s disturbing because I’m seeing the contamination firsthand, and practically no one else is looking at it,” Vorst said. “We’ve now established that contaminants do exist in recycled plastics, so the next step is to measure the public intake level of those contaminants.”

Vorst’s laboratory is chock full of plastic, both clear “virgin resin” and more yellowish recycled resin, and he explained most of his day-to-day research consists of heating or cooling plastic in one of the lab’s three large hot/cold chambers (which can go from zero to 110 degrees Fahrenheit). Afterward, that plastic is run against a “clean” baseline resin, and any “unknown” signatures are sorted into various categories of contaminants.

Vorst has found small, but alarming, amounts of chromium, cadmium, lead, mercury, antimony, and nickel in commercially used plastics tested at his laboratory.

Another major contaminant is Bisphenol A (BPA), a chemical which, according to multiple studies, can negatively affect the human hormone system, particularly at an early age. Though the scientific debate over whether or not BPA exposure is truly damaging to human health is raging back and forth, Vorst said he falls on the side of caution and advocates for cleaner plastics.

“This is personal for me, because I have been researching this issue for seven years, I have seen some truly bad players in the industry, and I have an autistic son,” Vorst said. “Plastic safety is just gaining national attention now, and we are at the forefront of this massive issue.”

Just after speaking with New Times, Vorst was contacted by the National Science Foundation, and said he hopes to secure funding from that organization to fund further research evaluating the potential negative neurological effects of contaminated plastics.

“It’s not glamorous research, looking at recycled plastic and diverted garbage,” Vorst said. “My colleagues and I dumpster dive all the time, though, and we think it’s worth it.”

Small satellites, big results

For many years, space remained the final frontier for many smaller universities like Cal Poly, unable to provide the economies of scale and pure cash necessary to send bulky, wildly expensive satellites into orbit.

To solve this large problem, aerospace engineering professor Dr. Jordi Puig-Suari and his students decided to think small. Really small.

To be exact, Puig-Suari developed the CubeSat technology—essentially, low cost “nanosatellites” which are four-inch cubes that have a volume of about a quart, and weigh about three pounds.

Though CubeSats—first proposed, designed, and standardized by a joint Cal Poly and Stanford effort in 1999—have long been a Cal Poly research standout, recent years have seen even greater proliferation and improvement of the technology, with Cal Poly firmly at the forefront.

“The CubeSat launches are like heaven for space nerds, and hearing the satellites transmit from space is still a thrill,” Puig-Suari said. “You hear a beep, and you know it was the same piece of hardware that was on your table last week—and now it’s up there.”

Puig-Suari, a native Spaniard who came to America for college, is definitely at home among the complicated circuitry and beeping satellite tracking programs festooning Poly’s two separate CubeSat laboratories.

Though the first CubeSat was sent into space back in 2003 and roughly 150 have been launched since then, Puig-Suari still geeks out about last week’s unprecedented flurry of launches, which sent almost 60 CubeSats into low orbit. Puig-Suari, his staff, and his students helped out with the deployment and launch coordination for some of those CubeSats, and they are currently trying to triangulate and identify the spacecraft via HAM radio frequency scanners.

“Last week was insane, and the whole recent CubeSat explosion has blown us away,” said Puig-Suari, his eyes eagerly scanning a promising-looking radio frequency blip. “As the numbers of people launching CubeSats go up, the good ideas will also go up exponentially.”

Puig-Suari’s team plans to launch their next CubeSat (along with seven others from partner institutions) on an Atlas V rocket blasting off from Vandenberg Air Force Base on Dec. 6.

CubeSats are probably Cal Poly’s most popular and well-publicized research project, and that popularity comes across inside the CubeSat lab. Even though it’s mid-afternoon on a sleepy Monday, between 10 and 15 students from all over the map—electrical engineers, computer scientists, and aerospace engineers alike—are eagerly tinkering away at work benches and laptops.

Puig-Suari seems to be on a first-name basis with almost all of the students and well versed in their projects. He takes laps around the lab, pointing out the various intricacies and highlights. Many of these projects, he mentioned, will turn into senior projects or master’s theses.

Back in his office, Puig-Suari explained that the CubeSat technology, with its low entry cost and open-source design standard, has recently kick-started numerous inaugural space efforts for many nations—among them Vietnam, Estonia, Poland, Peru, and Ecuador.

“It’s really amazing to facilitate access to space for other people and countries,” Puig-Suari said. “We’re doing it like the big boys, just smaller.”

Once in low orbit, the CubeSats—which circle the Earth roughly once every 90 minutes—perform a wide variety of experiments.

Some CubeSats collect data on space weather, some test radio or communication protocols and algorithms, some take pictures and videos, some test new batteries and sensors, and some even conduct biology experiments.

In one infamous example from 2007, one CubeSat managed to snap and transmit a picture of another CubeSat that was orbiting right next to it (New Times Staff Photographer Steve E. Miller dubbed this a “satellite selfie.”)

As Moore’s Law predicts, computer-processing power has grown exponentially in recent years, allowing electronics that are growing in sophistication and shrinking in size to be inserted in increasingly adept CubeSats.

That said, some of the CubeSats have failed to launch or operate properly (and most will start to disintegrate after a year or so in orbit), but managing failure is all part of the CubeSat ethos, Puig-Suari said.

“The speed of progress is crazy, and we’re riding that wave into space,” Puig-Suari said. “I think amazing things will continue to happen.”

Getting emotional about food

As her colleagues turn to advanced machinery and space for their research efforts, Dr. Amy Lammert has found fulfilling, boundary-pushing research with tangible impacts right here on Earth, with something as seemingly basic as food.

Lammert, an assistant professor in Cal Poly’s Food Science and Nutrition department, conducts sensory tests on consumers to measure their emotional responses to various types of foods.

“Essentially, we study consumer behaviors and responses so that we can create smarter and healthier food products that they’re willing to eat over and over again,” Lammert said. “We want to better understand the drivers of what people want to eat.”

Thus far, Lammert’s research has focused on orange soda, cheese, and flavored milks. Research subjects eat “healthier” versions of these foods (often with sodium, fat, or sugar levels reduced and offset by different flavor enhancers).

Afterward, the participants are asked a variety of questions about the sensory experience of the food, assessing their answers based on evocative pictures of positive, negative, and neutral emotions—tied to a nine-point scale with verbal anchors.

“What we realized is that consumer insights can’t just end at ‘I like it,’” Lammert said. “Emotions, needs, and abstract thoughts are all part of the decision-making process, and we’re looking at the role that emotions play in evaluating a food product.”

Such nuanced sensory tests in the food science area are fairly newfangled (the first research papers on the subject came out in 2009 and 2010), and Lammert’s efforts to embrace human variability are slowly taking root in the food testing industry.

“We can help businesses make better decisions, and companies are starting to recognize that need—sensory testing is being given greater weight in the new product decision-making process,” said Kristine Martinez, one of Lammert’s food science graduate students.

Martinez and her classmate Malori Comer, also a food science grad student, are deeply involved in the research process: signing up participants, conducting statistical analyses, giving presentations, and even making the low-sodium cheese.

Clad in unflattering (but scientifically necessary) hairnets, Lammert, Martinez, and Comer walk around their stomping ground—the food processing laboratory. Lammert, who seems to smile perpetually, is approached by a graduate student bearing an experimental dessert tortilla. She breaks off a piece and tastes it.

“Good job, but less cinnamon,” Lammert says.

Though much of the food formulation goes on in this lab, Lammert said her research team is working to have participants connect to their questionnaires from their homes, on the Internet or on the phone.

“What’s missing in a typical ‘white booth’ is context,” Lammert explained.

Lammert said initial feedback from early testing on low- and reduced-sodium cheeses made in the Poly labs has been positive, with consumers connecting the cheese to positive emotions.

“We’re still early in the process, so our biggest hurdle is continuing to get the right consumers who fit the right profile,” Lammert said. “We’re excited to get more actionable information about our products.”

Sometimes, Comer added, consumers don’t know what they want until it’s offered.

“We see ourselves as the liaison between food chemists and consumers,” Lammert said. “If the consumer can be happier and healthier, then it’s a win win.”

The research boom

For interim Dean of Research Wendt, the research boom he has partially overseen is also something of a personal victory. During Wendt’s undergraduate years at Cal Poly studying marine science, he said the only downside in an otherwise fantastic experience was the fact that he had to go off-campus to do his senior project research—as there were limited research opportunities on campus.

“Nowadays, one in five of our professors is externally funded for their research, and that ratio used to be much, much smaller,” Wendt said. “I think we’re augmenting what we already have at Poly with greater opportunities for students and professors.”

Wendt is putting his money where his mouth is—he is also a marine biologist and the director of Poly’s Center for Coastal Marine Sciences, and has personally pulled in between eight and nine million dollars in external funding from private companies, federal and state grants, and foundations during his tenure.

As the shift toward more research continues, Wendt said the difficult part for Cal Poly will be maintaining the necessary balance between teaching and research, while also making sure the university’s funding is stable.

“I think research is the great expander, because it gets your message out into the world,” Wendt said. “We’re using research to involve students, solve real world problems, and exit the Ivory Tower.”

Staff Writer Rhys Heyden can be reached at [email protected].

Latest in News

Readers also liked…

-

Coast Unified teachers upset over new position's salary and qualifications

Oct 20, 2022 -

SLO police identify alleged driver who hit and killed couple

Dec 22, 2022 -

When the levee breaks: Oceano residents, county officials walk a tightrope of regulations to manage Arroyo Grande Creek, which some say led to the levee's failure in January

May 18, 2023